XBroom Sweeper Control Computer

Large PLC 12″ Touchscreen XBroom Control Computer

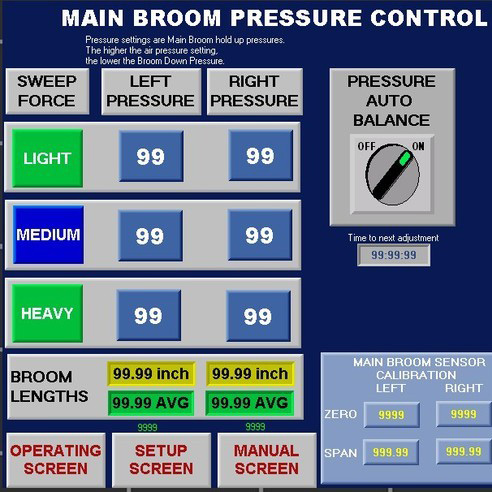

The control used on the XBroom is an industrial grade Programmable Logic Controller (PLC) with a touch-screen display panel. All functions of the broom are controlled by the PLC. This enables fully automatic operation of the sweeping operation. The operator just touches a “Start” button and the PLC activates the functions needed to sweep. This involves starting, lowering, and extending the gutter brooms, starting the elevator and lowering to the desired height, lowering the skid shoes and main broom, starting the broom motor, opening the water spray valves and starting the water pumps. The PLC always monitors the position of the elevator, ensuring that it is fully forward before starting. It also monitors the hydraulic temperature and level and will raise all brooms if the transmission is placed in reverse. There is a “Pause” button that will stop brooms and water sprays if the sweeper has to stop for traffic without raising the brooms or elevator. The “Stop” button will stop and raise all brooms and the elevator will continue to run for 6 seconds to empty out.

The 4-way joystick that is easily reached from either operators station is used for starting and stopping the sweep operation and turning on or off the two gutter brooms. This eliminates the need to look at the screen for normal operation. The screen is not required for the broom to operate.

The PLC has an hour meter for each broom, the elevator, water pumps, hydraulic fan, and PTO. The PLC also keeps a count on how many times the hopper has dumped. This lets you track broom wear to actual operating hours of the individual broom.

There is a screen for Manual Operation of each function for testing and diagnostics. The buttons also give a visual indication of what is “on” and the status of each limit switch. The PLC greatly simplifies the wiring to the valves and solenoids on the broom (One 3/4″ conduit containing 3 cables)

The hopper dumping functions can be either controlled from the touch-screen or from the joystick on the front panel. When the hopper needs to be dumped, the PLC will move the elevator back before raising the hopper, then ensure the hopper is down before moving the elevator to the forward position.